Adelaide Motors - Ergonomic Assessment

Project Type

Physical Ergonomics

Year

2024

Introduction

Adelaide Motor is a car repair and sales business based in London, Ontario. The jobs of mechanics are dependent on customer demands, but tire changes are especially common around the beginning of the winter season. In November 2023, I visited Adelaide Motor to conduct an ergonomic analysis on tire change as an act of a proactive approach to ergonomics.

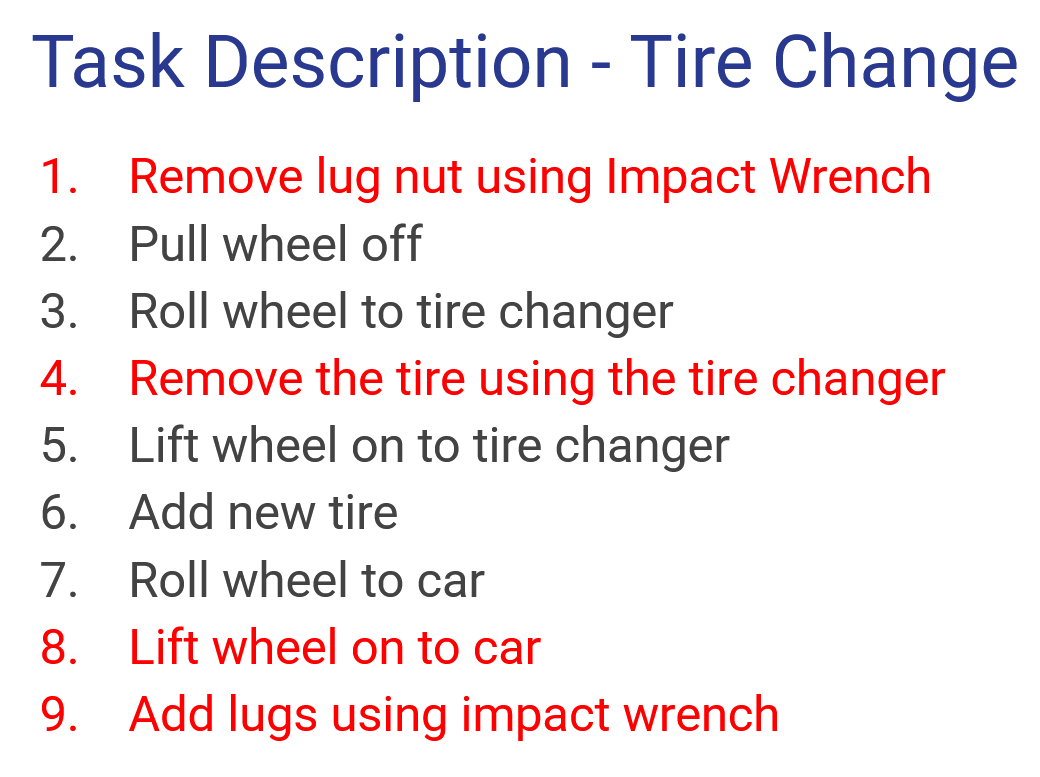

Creating a Job Description

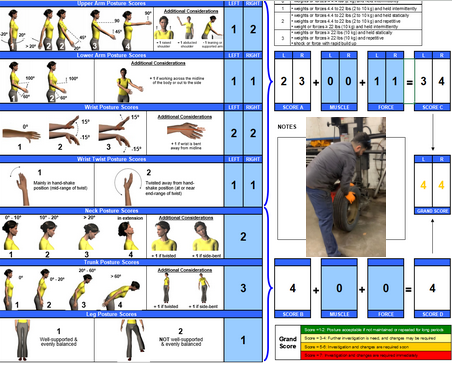

Before conducting any analysis I had to simply shadow and observe the worker. I would try to allow the mechanic to work and only ask questions when necessary. After returning from Adelaide Motor from collecting data, I had composed a task description for the task of tire changes. VelocityEHS was used and a system similar to a REBA was used to screen all the task description items using the worst posture from each task, in order to create a more conservative estimate. Four of the Nine tasks related to the tire change were found as the most problematic and further investigagted. The list on the left is a task break down with items in red being the tasks that were considered problematic.

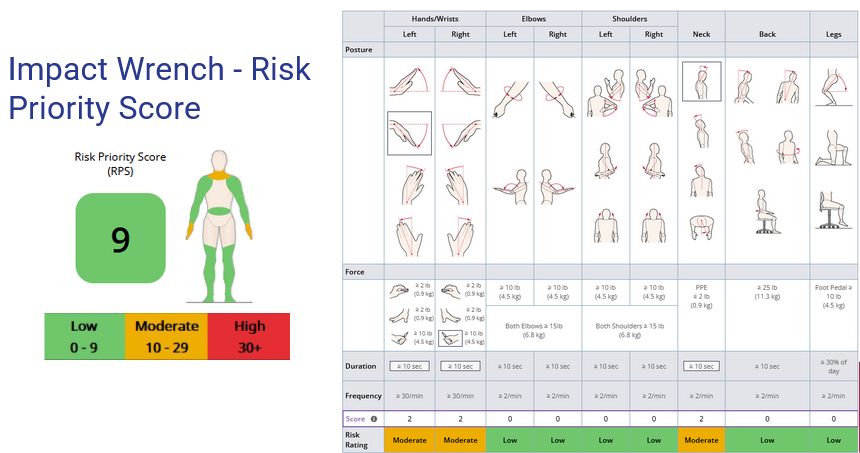

Impact Wrench - Risk Priority Score (RPI)

The impact wrench portion of the task is to remove the lug nuts of the tire to remove the tire or to place lug nuts to secure the tire. Both putting in and taking out the lug nuts are grouped together as the only difference is with the push force needed to secure the lug nut. However, if the push force is accounted for and the task is deemed safe, then the "easier" removal process should also be considered safe in this case as well. Using the impact wrench to remove or place the lugs had an RPI score of nine which is considered low by VelocityEHS.

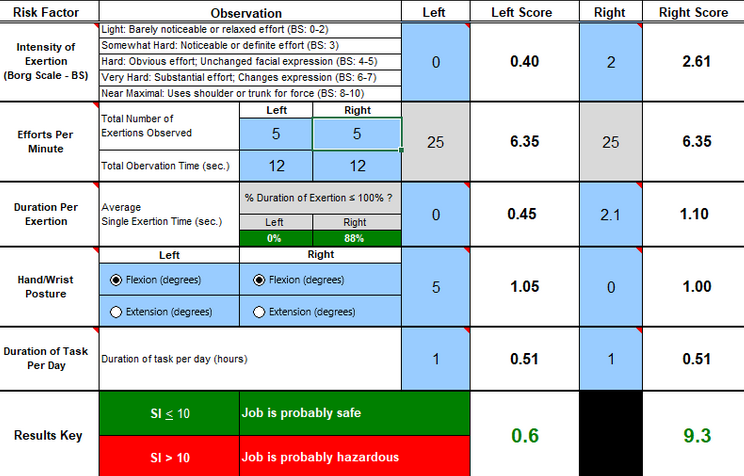

Impact Wrench - Strain Index

Although the RPI score was low I had conducted a strain index to measure the right wrist as there is an exertion to remove/add the lug nut. However, the strain index indicated a score of 9.3. Although it is on the upper bounds, it still indicates that the job is probably safe. From here I moved on to measure other tasks regarding the tire change to determine what task has the highest ergonomic risk.

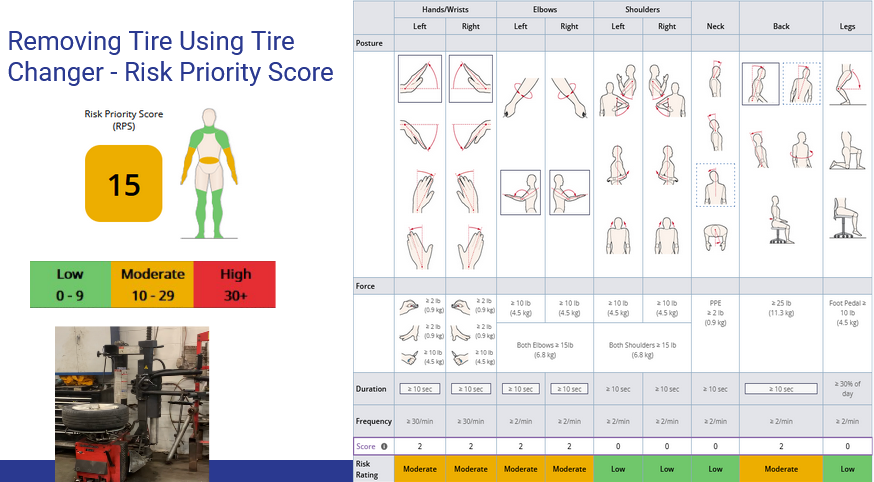

Removing the Tire Using a Tire Changer - RPI

The second task was removing the tire using a swing arm tire changer. The tire changer is a tool used by mechanics in order to remove the tire from the wheel and add a new tire on to it. The wheel is separated using the edges called “bead breakers” that separate the tire from the wheel. The RPI score for this task was 15 and was measured when the mechanic used the bead breakers on the side section. I chose to do this posture because the mechanic preferred to use that portion of the tire changer to remove the tire.

Removing the Tire Using a Tire Changer - RPI

I decided to also conduct a RULA as this this was mostly a postural concern rather than one regarding force. The posture was held for approximately 28 seconds and the biggest problems were in the wrists. The score was a 4 which indicates that changes may be required.

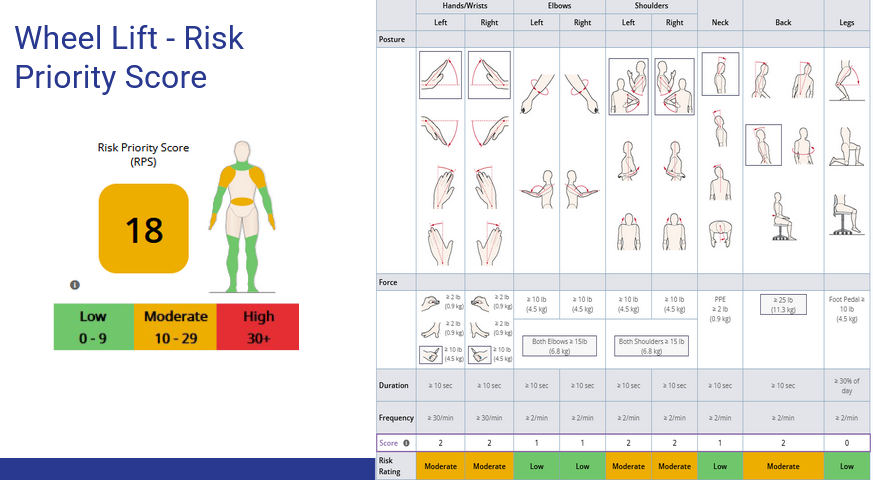

Wheel Lift - RPI

The final task analyzed was the wheel lift. The wheel must be lifted up and back onto the car before securing it with an impact wrench. I had assumed the weight of the wheel was 20.4kg (45 lbs). The Risk Priority Score (RPI) was 18. This was the highest risk priority score of all the tasks covered and was the one I had decided to focus on.

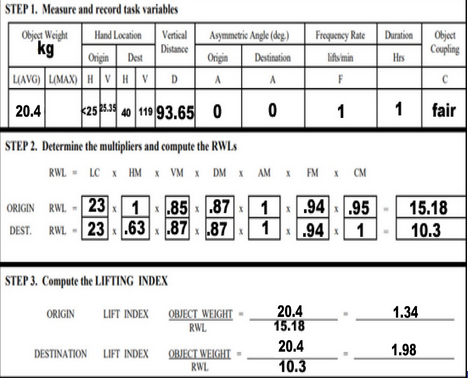

Wheel Lift - NIOSH

I first started a deeper dive analysis by starting with a NIOSH as the worker must lift the tire up to the car's wheel height as the car is on a car lift as the task is being done. The lifting index for the origin was 1.34, and the lifting index for the destination was 1.98. This indicates that there may be an increased risk of injury for this task. However, it is important to note that the lifting destination height may vary as the height to which the mechanic lifts the car is variable.

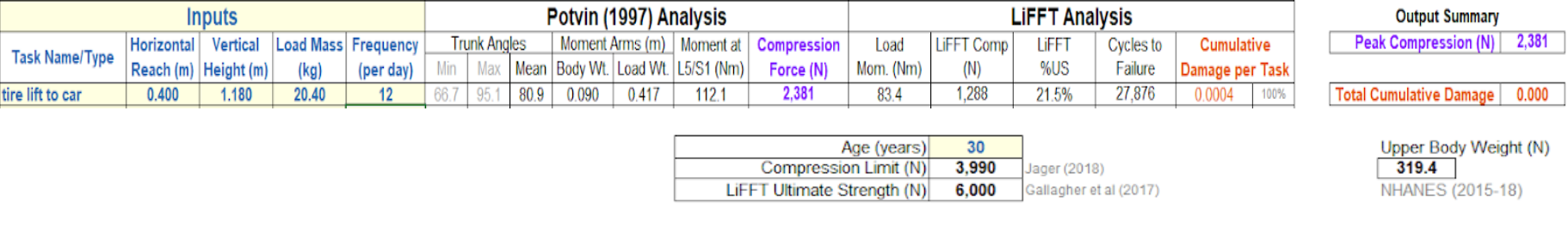

Wheel Lift - Lumbar Compression

Next, I decided to measure for any lumbar compression for the task of lifting the wheel. I had assumed that the tire's weight is 20.4kg (45lbs) and that a single mechanic did three cars (twelve wheels) in a day. Lumbar compression was conducted for the twenty-fifth percentile female and found that peak compression was 2,381N with the compression limit being 3990N. The peak compression falling well below the compression limit indicates that there is a low risk of lumbar compression from this task.

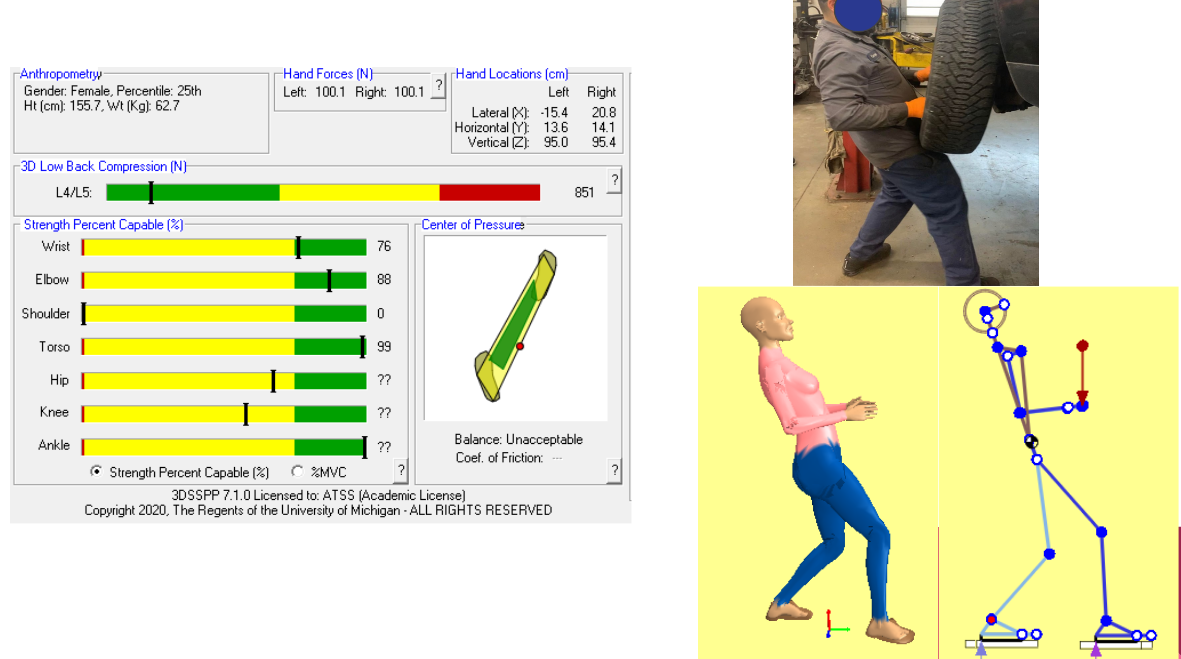

Wheel Lift - Michigan 3DSSPP

I had done a 3D static analysis for the wheel lift as well. As can be seen the biggest issue with the lift is at the shoulders as 0% of the 25th percentile female being able complete this task. This is because of the load being placed on the arm as the worker tries to hold the tire to place it on to the car. However, a limitation of this is that, as you can see in the top photo, the worker is supporting some of that weight on his leg, which is likely offsetting some of that weight affecting the shoulder. This was not accounted for in the 3D static program. Also, another limitation of the Michigan’s 3DSSPP is that the shoulder measure is not as accurately measured as other parts are.

Direct & Root Causes and Solution - Lifting the Wheel

With the wheel lift being the task that had the highest risk for ergonomic injury it was further investigated. I looked at both the direct causes and root causes to better understand the problem at hand and to find a recommendation that is an appropriate solution for this. The recommendations, considering it is a small business, must address the problem and be cost-effective. I gave three recommendations so that the owner may choose; however, I personally believed that the third recommendation was the best solution.

Direct Cause

Force of the wheel applied to the worker.

Height of where the wheel has to be placed.

Root Cause

Wheels have to be lifted in order to place it on to the car.

Workers have no assistance when lifting the wheel.

Wheel weight can’t change.

The height of the car can be adjusted but often isn’t.

Reasons why may include it is an extra step and therefore will take extra time leading the mechanic to take extra time to complete the task

Recommendation 1 - Lowering the Height of the Car

The height of the car is first set at a comfortable position for the mechanic to remove the lug nuts on the wheel. However, afterwards, it is not adjusted again. I recommend decreasing the height after removing all the wheels on the car so that when the mechanic lifts the wheel into place, he does not have to bring the wheel as high as he needs to. The recommended height change is 70cm. By changing the height to 70cms you decrease the vertical distance and the distance in vertical travel to become 44.65cms. This would decrease the NIOSH destination score from 1.98 to 1.64. However, this solution is largely dependent on the worker's behaviour, and if that worker does not believe it is worth taking the extra step of lowering the car, they may not do it.

This recommendation option is given as it does not cost the small business anything but still should address the issue enough to have some impact on affected workers.

Recommendation 2 - Wheel Lifter

The second solution is to purchase a wheel lifter. The cost would be approximately $2800.

This would help as it completely eliminates the lifting and lowering portion that is needed when changing the wheel. All the mechanic has to do is attach the wheel to the wheel lifter using likely a belt (which may vary depending on the model) and then pull the machine out with the tire now attached. From here, the machine can be pushed to where it is needed, and a button can be pressed in order to raise or lower the wheel. This recommendation is more costly but was designed to directly address the issue of lifting wheels.

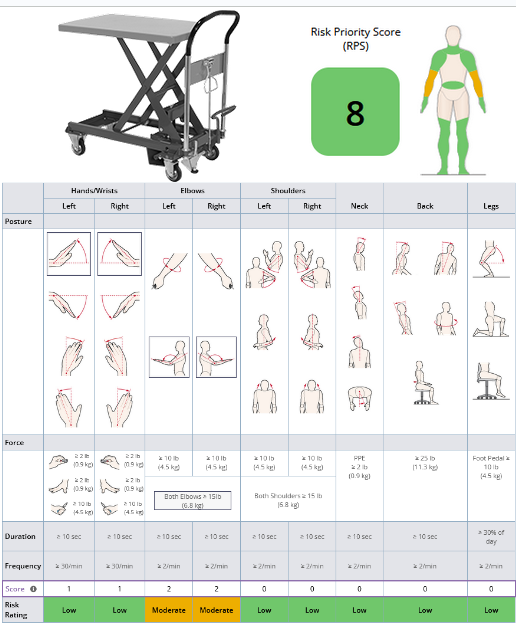

Recommendation 3 - Lift Table

Similar to the second solution is to purchase a lift table as it also is to eliminate the lifting. The cost would be approximately $1300. Since wheels and tools are mostly being placed on the lift tables, the capacity won’t need to be too high. And at this price range you may get a lift table with a capacity of approximately 500 lb.

The difference here is that although this is a much cheaper option it is not as specialized as the wheel lifter. And introduces a push which is much less risky as indicated by the RPI score of 8. However, there may be other uses for the lift table making it a more flexible tool for the workshop

This was the recommendation I believed would benefit Adelaide Motors the most because of how it addresses the ergonomic problem while also being a flexible tool that can be used in other scenarios.

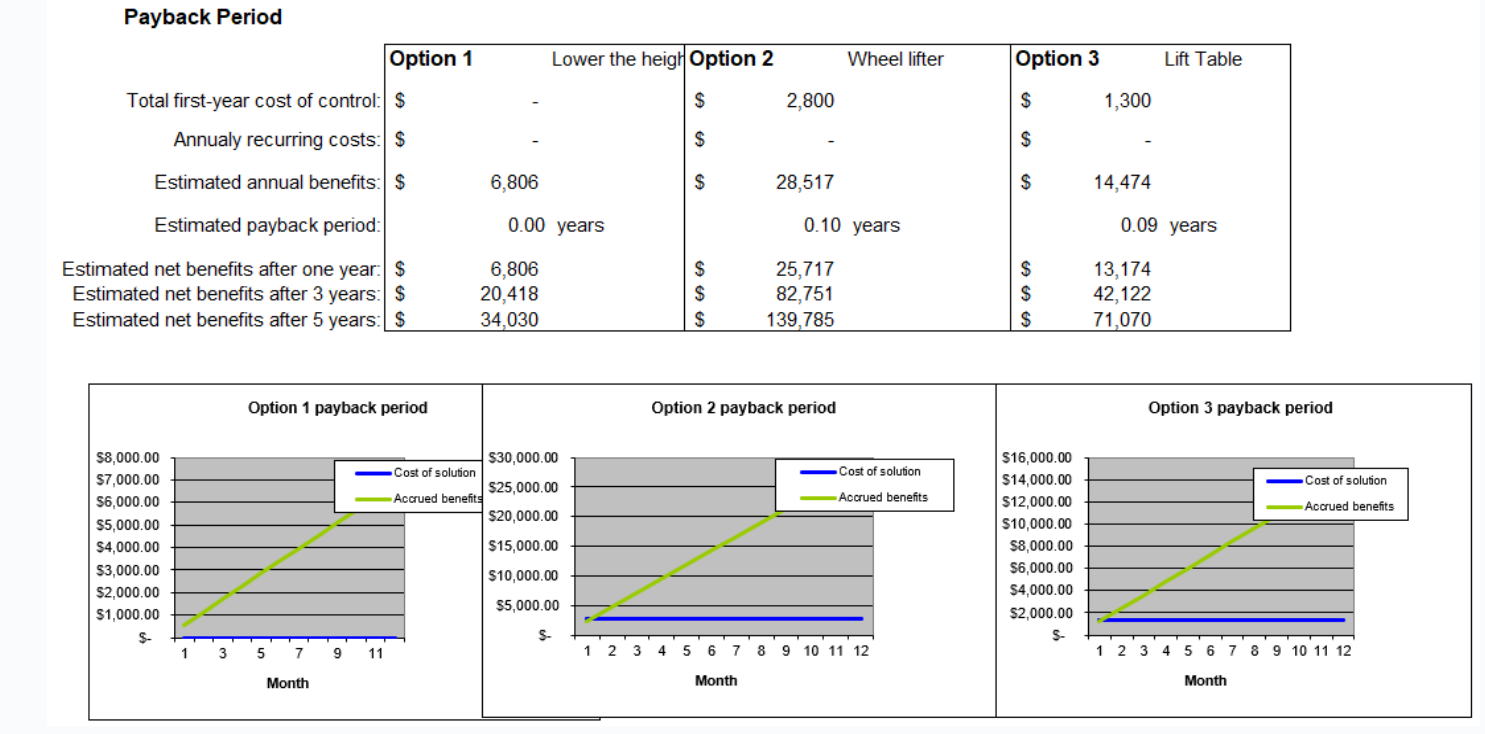

Return on Investment

With the shoulders being the area of concern for the worker when lifting the tire I had input one upper extremity injury which comes at an approximate $1959 annual MSD claim costs with an estimated annual indirect cost of $2351 totalling to $5877.

According to this data analysis with just lowering the height Adelaide Motors may see a net benefit of $6,806 in a year, with the wheel lifter the net benefit is $25,717 in a year and the net benefit of the lift table is $13,174 in a year. For more information consult the related image. However, one thing that this does not consider is the add use of the lift table and how it may increase productivity in other areas of the mechanics shop.